APPLICATION of 0.6/1 kV LT PVC insulated power cable

0.6/1 kV LT PVC insulated power cable are used for electricity supply in low voltage installation system, They are suitable for installation in indoors and outdoors, in cable ducts, underground, in power and switching stations, local energy distributions, industrial plants, where there is no risk of mechanical damage.

STANDARD of 0.6/1 kV LT PVC insulated power cable

IEC 60502-1

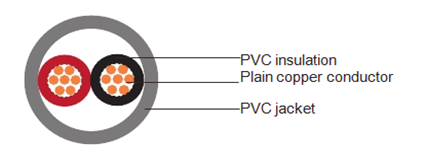

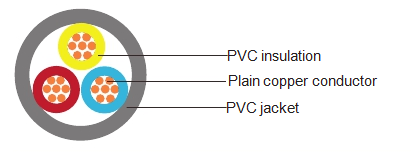

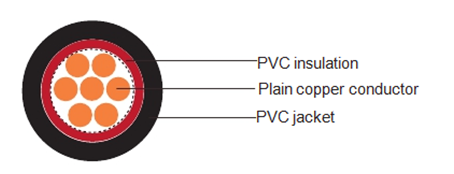

CONSTRUCTION of 0.6/1 kV LT PVC insulated power cable

Conductors: The conductors shall be either of Class 1 or Class 2 of plain or metal-coated annealed copper or of plain aluminum or aluminum alloy, or of Class 5 of plain or metal-coated copper in accordance with IEC 60228.

Insulation: PVC Insulation material and thickness shall be as per IEC 60502-1, PVC material shall be Type A as per IEC 60502-1.

Color Code

Color Code (1) :

1 Core : Red or Black

2 Cores : Red, Black

3 Cores : Red, Yellow, Blue

4 Cores : Red, Yellow, Blue, Black

5 Cores : Red, Yellow, Blue, Black, Green

Above 5 Cores: Black Cores with White numerals

Color Code (2) :

1 Core : Brown or Blue

2 Cores : Brown, Blue

3 Cores : Brown, Black, Grey

4 Cores : Blue, Brown, Black, Grey

5 Cores : Green/Yellow, Blue, Brown, Black, Grey

Above 5 Cores: Black Cores with White numerals

Other colors can be manufactured upon request.

Assembly/ Inner Covering: The inner coverings may be extruded or lapped. For cables with circular cores, except cables with more than five cores, a lapped inner covering shall be permitted only if the interstices between the cores are substantially filled. A suitable binder is permitted before application of an extruded inner covering. The materials used for inner coverings and fillers shall be suitable for the operating temperature of the cable and compatible with the insulating material. For halogen free cables, the inner covering and fillers shall also be halogen free compound.

Armor: Aluminum/galvanized steel/steel wires applied helically over the Inner Covering as per IEC 60502-1, or double aluminum/steel tapes and copper/tinned copper wire can also be manufactured upon request.

Outer Sheath: Outer sheath shall be of extruded PVC Type ST1/ST2 as per IEC 60502-1,Polyethylene type ST3/ST7, Halogen free compound ST8, Polychloroprene, chlorosulfonated polyethylene or similar polymers, type SE1 are also available on request.

Fire Performance of Cable Sheaths: Cables can be supplied with special flame retardant PVC outer sheath to comply with the flame test requirements of IEC 60332-3-22, IEC 60332-3-23 and IEC 60332-3-24, Halogen Free material comply to IEC60754-1/2 and IEC 60684-2.

CONSTRUCTION PARAMETER of 0.6/1 kV LT PVC insulated power cab

|

Nominal Cross |

Diameter of |

Nominal |

Nominal Sheath |

Overall Diameter |

|

Section |

Conductor |

Insulation |

Thickness |

(Approx.) |

|

(Approx.) |

Thickness |

|||

|

mm² |

mm |

mm |

mm |

mm |

|

1x4 |

2.3 |

1 |

1.4 |

7.1 |

|

1x6 |

2.8 |

1 |

1.4 |

7.6 |

|

1x10 |

3.6 |

1 |

1.4 |

8.4 |

|

1x16 |

4.5 |

1 |

1.4 |

9.3 |

|

1x25 |

5.6 |

1.2 |

1.4 |

10.8 |

|

1x35 |

6.7 |

1.2 |

1.4 |

11.9 |

|

1x50 |

8 |

1.4 |

1.4 |

13.6 |

|

1x70 |

9.4 |

1.4 |

1.4 |

15.1 |

|

1x95 |

11 |

1.6 |

1.5 |

17.2 |

|

1x120 |

12.4 |

1.6 |

1.5 |

18.7 |

|

1x150 |

13.8 |

1.8 |

1.6 |

20.6 |

|

1x185 |

15.3 |

2 |

1.7 |

22.7 |

|

1x240 |

17.5 |

2.2 |

1.8 |

25.4 |

|

1x300 |

19.5 |

2.4 |

1.9 |

28 |

|

1x400 |

22.6 |

2.6 |

2 |

31.7 |

|

1x500 |

25.2 |

2.8 |

2.1 |

35 |

|

1x630 |

28.3 |

2.8 |

2.2 |

38.3 |

|

Two cores(unarmoured) |

|

|||

|

Nominal Cross |

Diameter of |

Nominal |

Nominal Sheath |

Overall Diameter |

|

Section |

Conductor |

Insulation |

Thickness |

(Approx.) |

|

(Approx.) |

Thickness |

|||

|

mm² |

mm |

mm |

mm |

mm |

|

2x1.5 |

1.4 |

0.8 |

1.8 |

9.6 |

|

2x2.5 |

1.8 |

0.8 |

1.8 |

10.4 |

|

2x4 |

2.3 |

1 |

1.8 |

12.2 |

|

2x6 |

2.8 |

1 |

1.8 |

13.2 |

|

2x10 |

3.6 |

1 |

1.8 |

14.8 |

|

2x16 |

4.5 |

1 |

1.8 |

16.6 |

|

2x25 |

5.6 |

1.2 |

1.8 |

19.6 |

|

2x35 |

6.7 |

1.2 |

1.8 |

21.8 |

|

2x50 |

8 |

1.4 |

1.8 |

25.2 |

|

2x70 |

9.4 |

1.4 |

1.9 |

28.1 |

|

2x95 |

11 |

1.6 |

2 |

32.4 |

|

2x120 |

12.4 |

1.6 |

2.1 |

35.4 |

|

2x150 |

13.8 |

1.8 |

2.2 |

39.2 |

|

2x185 |

15.3 |

2 |

2.4 |

43.3 |

|

2x240 |

17.5 |

2.2 |

2.5 |

48.9 |

|

2x300 |

19.5 |

2.4 |

2.7 |

54 |

|

2x400 |

22.6 |

2.6 |

2.9 |

61.5 |

|

Three cores(unarmoured)

|

||||

|

Nominal Cross |

Diameter of |

Nominal |

Nominal Sheath |

Overall Diameter |

|

Section |

Conductor |

Insulation |

Thickness |

(Approx.) |

|

(Approx.) |

Thickness |

|||

|

mm² |

mm |

mm |

mm |

mm |

|

3x1.5 |

1.4 |

0.8 |

1.8 |

10.1 |

|

3x2.5 |

1.8 |

0.8 |

1.8 |

10.9 |

|

3x4 |

2.3 |

1 |

1.8 |

12.9 |

|

3x6 |

2.8 |

1 |

1.8 |

13.9 |

|

3x10 |

3.6 |

1 |

1.8 |

15.7 |

|

3x16 |

4.5 |

1 |

1.8 |

17.6 |

|

3x25 |

5.6 |

1.2 |

1.8 |

20.8 |

|

3x35 |

6.7 |

1.2 |

1.8 |

23.2 |

|

3x50 |

8 |

1.4 |

1.8 |

26.9 |

|

3x70 |

9.4 |

1.4 |

1.9 |

30.1 |

|

3x95 |

11 |

1.6 |

2.1 |

34.7 |

|

3x120 |

12.4 |

1.6 |

2.2 |

38 |

|

3x150 |

13.8 |

1.8 |

2.3 |

42.1 |

|

3x185 |

15.3 |

2 |

2.5 |

46.5 |

|

3x240 |

17.5 |

2.2 |

2.7 |

52.5 |

|

3x300 |

19.5 |

2.4 |

2.8 |

58 |

|

3x400 |

22.6 |

2.6 |

3.1 |

66.1 |

.jpg)