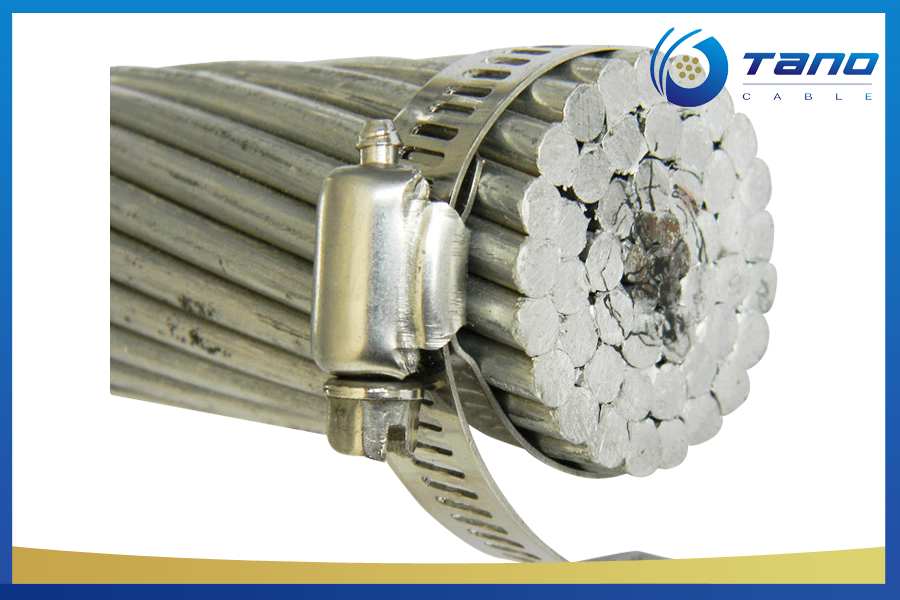

ACSR conductors are widely used for electrical power transmission over long distances, since they are ideal for long overhead lines spans. They are also used as a messenger for supporting overhead electrical cables.

STANDARD

Basic design to DIN 48204 standard.

CONSTRUCTION

ACSR conductors are formed by several wires of aluminium and galvanized steel, stranded in concentric layers. The wire or wires which form the core, are made of galvanized steel and the external layer or layers, are of aluminium. Galvanized steel core consist normally of 1, 7 or 19 wires. The diameters of steel and aluminium wires can be the same, or different. By varying the relative proportions of aluminium and steel, the required characteristics for any particular application can be reached. A higher U. T. S. Can be obtained, by increasing steel content, and a higher current carrying capacity by increasing aluminium content.

ELECTRICAL PROPERTIES

| Density@20ºC | Aluminum: 2.703 kg/dm |

| Galvanized Steel: 7.80 kg/dm | |

| Temperature Coefficient@20°C | Aluminum: 0.00403 (°C) |

| Resistivity@20°C | Aluminum: Should not exceed 0.028264 |

| Linear Expansivity | Aluminum: 23 x10 (°C) |

| Galvanized Steel: 11.5 x10 (1/°C) |

SERVICE CONDITIONS

| Ambient Temperature | -5°C - 50°C |

| Wind Pressure | 80 – 130kg/m2 |

| Seismic Acceleration | 0.12 - 0.05g |

| Isokeraunic Level | 10 – 18 |

| Relative Humidity | 5 – 100% |

CONSTRUCTION PARAMETERS

| Nominal | Sectional Area | Stranding | Weight | ||||||||

| Sectional | Overall | Breaking | Electrical | Current | |||||||

| Area | Diameter | Load | Resistance | Rating* | |||||||

| AL | Steel | AL | Steel | Total | AL | Steel | @20º | ||||

| mm2 | mm2 | mm2 | mm2 | mm2 | No.×mm | No.×mm | mm | Kg/Km | KN | Ω/Km | A |

| 16 | 2.5 | 15.27 | 2.54 | 17.8 | 6/1.80 | 1/1.80 | 5.4 | 62 | 5.81 | 1.8793 | 83 |

| 25 | 4 | 23.86 | 3.98 | 27.8 | 6/2.25 | 1/2.25 | 6.8 | 97 | 9.02 | 1.2028 | 109 |

| 35 | 6 | 34.35 | 5.73 | 40.1 | 6/2.70 | 1/2.70 | 8.1 | 140 | 12.7 | 0.8353 | 136 |

| 44 | 32 | 43.98 | 31.67 | 75.7 | 14/2.00 | 7/2.40 | 11.2 | 373 | 45.46 | 0.6573 | 166 |

| 50 | 8 | 48.25 | 8.04 | 56.3 | 6/3.20 | 1/3.20 | 9.6 | 196 | 17.18 | 0.5946 | 168 |

| 50 | 30 | 51.17 | 29.85 | 81 | 12/2.33 | 7/2.33 | 11.7 | 378 | 44.28 | 0.5644 | 181 |

| 70 | 12 | 69.89 | 11.4 | 81.3 | 26/1.85 | 7/1.44 | 11.7 | 284 | 26.31 | 0.413 | 211 |

| 95 | 15 | 94.39 | 15.33 | 109.7 | 26/2.15 | 7/1.67 | 13.6 | 383 | 35.17 | 0.3058 | 254 |

| 95 | 55 | 96.51 | 56.3 | 152.8 | 12/3.20 | 7/3.20 | 16 | 714 | 80.2 | 0.2992 | 267 |

| 105* | 75 | 105.67 | 75.55 | 181.2 | 14/3.10 | 19/2.25 | 17.5 | 899 | 106.69 | 0.2736 | 284 |

| 120 | 20 | 121.57 | 19.85 | 141.4 | 26/2.44 | 7/1.90 | 15.5 | 494 | 44.94 | 0.2374 | 297 |

| 120 | 70 | 122.15 | 71.25 | 193.4 | 12/3.60 | 7/3.60 | 18 | 904 | 98.16 | 0.2364 | 308 |

| 125 | 30 | 127.92 | 29.85 | 157.8 | 30/2.33 | 7/2.33 | 16.3 | 590 | 57.86 | 0.2259 | 308 |

| 150 | 25 | 148.86 | 24.25 | 173.1 | 26/2.70 | 7/2.10 | 17.1 | 604 | 54.37 | 0.1939 | 336 |

| 170 | 40 | 171.77 | 40.08 | 211.9 | 30/2.70 | 7/2.70 | 18.9 | 794 | 77.01 | 0.1682 | 369 |

| 185 | 30 | 183.78 | 29.85 | 213.6 | 26/3.00 | 7/2.33 | 19 | 744 | 66.28 | 0.1571 | 382 |

| 210 | 35 | 209.1 | 34.09 | 243.2 | 26/3.20 | 7/2.49 | 20.3 | 848 | 74.94 | 0.138 | 414 |

| 210 | 50 | 212.06 | 49.48 | 261.5 | 30/3.00 | 7/3.00 | 21 | 979 | 92.25 | 0.1363 | 420 |

| 230 | 30 | 230.91 | 29.85 | 260.8 | 24/3.50 | 7/2.33 | 21 | 874 | 73.09 | 0.1249 | 438 |

| 240 | 40 | 243.05 | 39.49 | 282.5 | 26/3.45 | 7/2.68 | 21.8 | 985 | 86.46 | 0.1188 | 453 |

| 265 | 35 | 263.66 | 34.09 | 297.8 | 24/3.74 | 7/2.49 | 22.4 | 998 | 82.94 | 0.1094 | 475 |

| 300 | 50 | 304.26 | 49.48 | 353.7 | 26/3.86 | 7/3.00 | 24.5 | 1233 | 105.09 | 0.0949 | 520 |

| 305 | 40 | 304.62 | 39.49 | 344.1 | 54/2.68 | 7/2.68 | 24.1 | 1155 | 99.3 | 0.0949 | 518 |

| 340 | 30 | 339.29 | 29.85 | 369.1 | 48/3.00 | 7/2.33 | 25 | 1174 | 92.56 | 0.0851 | 551 |

| 380 | 50 | 381.7 | 49.48 | 431.2 | 54/3.00 | 7/3.00 | 27 | 1448 | 120.91 | 0.0757 | 593 |

| 385 | 35 | 386.04 | 34.09 | 420.1 | 48/3.20 | 7/2.49 | 26.7 | 1336 | 104.31 | 0.0748 | 595 |

| 435 | 55 | 434.29 | 56.3 | 490.6 | 54/3.20 | 7/3.20 | 28.8 | 1647 | 136.27 | 0.0666 | 641 |

| 450 | 40 | 448.71 | 39.49 | 488.2 | 48/3.45 | 7/2.68 | 28.7 | 1553 | 120.19 | 0.0644 | 651 |

| 490 | 65 | 490.28 | 63.55 | 553.8 | 54/3.40 | 7/3.40 | 30.6 | 1860 | 152.85 | 0.059 | 689 |

| 550 | 70 | 549.65 | 71.25 | 620.9 | 54/3.60 | 7/3.60 | 32.4 | 2085 | 167.42 | 0.0526 | 737 |

| 560 | 50 | 561.7 | 49.48 | 611.2 | 48/3.86 | 7/3.00 | 32.2 | 1943 | 146.28 | 0.0514 | 744 |

| 680* | 85 | 678.58 | 85.95 | 764.5 | 54/4.00 | 19/2.40 | 36 | 2564 | 209.99 | 0.0426 | 834 |

TECHNICAL DATA

| Numbers of Wires | Final Modules of Elasticity | Coefficient of Linear Expansion | |||

| Al | Steel | Kg/mm2 | lb/in2 | 1/Cº | 1/Fº |

| 6 | 1 | 81 | 11.5 x106 | 19.1 x10-6 | 10.6 x10-6 |

| 6 | 7 | 77 | 11.0 x106 | 19.8 x10-6 | 11.0 x10-6 |

| 12 | 7 | 107 | 15.2 x106 | 15.3 x10-6 | 8.5 x10-6 |

| 18 | 1 | 67 | 9.5 x106 | 21.2 x10-6 | 11.8 x10-6 |

| 24 | 7 | 74 | 10.5 x106 | 19.6 x10-6 | 10.9 x10-6 |

| 26 | 7 | 77 | 10.9 x106 | 18.9 x10-6 | 10.5 x10-6 |

| 28 | 7 | 79 | 11.2 x106 | 18.4 x10-6 | 10.2 x10-6 |

| 30 | 7 | 82 | 11.6 x106 | 17.8 x10-6 | 9.9 x10-6 |

| 30 | 19 | 80 | 11.4 x106 | 18.0 x10-6 | 10.0 x10-6 |

| 32 | 19 | 82 | 11.7 x106 | 17.5 x10-6 | 9.7 x10-6 |

| 54 | 7 | 70 | 9.9 x106 | 19.3 x10-6 | 10.7 x10-6 |

| 54 | 19 | 68 | 9.7 x106 | 19.4 x10-6 | 10.8 x10-6 |