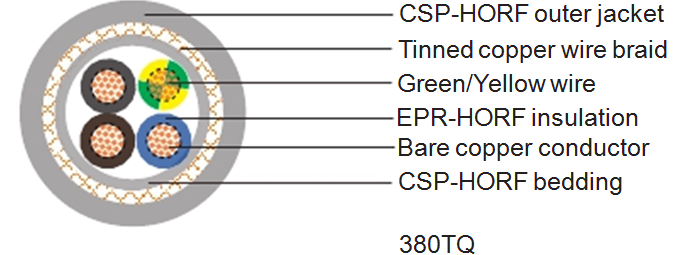

This range of Cables are designed for temporary building sites as extension leads for portable or fixed equipment. The copper braid prevents earth leakage and offers mechanical protection.

CONSTRUCTION :

Fine bare copper strands Stranding to BS 6360 CL-5 or IEC 60228 CL-5 EPR insulation CSP(Chlorosulphonated Polyethylene), HOFR (Heat and Oil Resistant and Flame Retardant) bedding TCWB(tinned copper wire braid) CSP(Chlorosulphonated Polyethylene), HOFR (Heat and Oil Resistant and Flame Retardant) sheath

CORE IDENTIFICATION

2 cores: Brown, Blue

3 cores: Green/Yellow + Brown, Blue

4 cores: Green/Yellow, Brown, Black, Grey

5 cores: Green/Yellow, Blue, Brown, Black, Grey

6 cores: and above: white insulation with black numerals

TECHNICAL DATA

Working voltage: 300/500 volts

Minimum bending radius: 8.0xOverall diameter

Temperature Range: -20º C to +85º C

Flame retardant: IEC 60332.1

Insulation resistance: 20 MΩxkm

CONSTRUCTION PARAMETER

| AWG | No. of Cores | Nominal | Nominal | ||||

| (No. of | x Nominal | Thickness | Thickness | Diameter | Nominal | Nominal | Nominal |

| Strands/ | Cross | of | of | of Braid | Thickness | Overall | Weight |

| Strand | Sectional | Insulation | Bedding | Wire | of Sheath | Diameter | |

| Diameter) | Area | ||||||

| No.xmm² | mm | mm | mm | mm | mm | kg/km | |

| 3802TQ | |||||||

| 18(24/32) | 2*0.75 | 0.6 | 0.8 | 0.2 | 1.1 | 9.7 | 149 |

| 17(32/32) | 2*1 | 0.6 | 0.9 | 0.2 | 1.1 | 10.3 | 169 |

| 16(30/30) | 2*1.5 | 0.8 | 1 | 0.2 | 1.3 | 12.3 | 236 |

| 14(50/30) | 2*2.5 | 0.9 | 1.1 | 0.2 | 1.4 | 13.9 | 307 |

| 3803TQ | |||||||

| 18(24/32) | 3*0.75 | 0.6 | 0.9 | 0.2 | 1.1 | 10.3 | 170 |

| 17(32/32) | 3*1 | 0.6 | 0.9 | 0.2 | 1.2 | 11 | 196 |

| 16(30/30) | 3*1.5 | 0.8 | 1.1 | 0.2 | 1.3 | 13.1 | 274 |

| 14(50/30) | 3*2.5 | 0.9 | 1.2 | 0.2 | 1.5 | 15 | 366 |

| 3804TQ | |||||||

| 18(24/32) | 4*0.75 | 0.6 | 0.9 | 0.2 | 1.2 | 11.1 | 198 |

| 17(32/32) | 4*1 | 0.6 | 1 | 0.2 | 1.2 | 11.8 | 227 |

| 16(30/30) | 4*1.5 | 0.8 | 1.1 | 0.2 | 1.4 | 14.1 | 319 |

| 14(50/30) | 4*2.5 | 0.9 | 1.3 | 0.2 | 1.6 | 16.4 | 441 |

| 3805TQ | |||||||

| 18(24/32) | 5*0.75 | 0.6 | 1 | 0.2 | 1.2 | 11.9 | 233 |

| 17(32/32) | 5*1 | 0.6 | 1 | 0.2 | 1.3 | 12.7 | 272 |

| 16(30/30) | 5*1.5 | 0.8 | 1.2 | 0.2 | 1.5 | 15.4 | 373 |

| 14(50/30) | 5*2.5 | 0.9 | 1.3 | 0.2 | 1.6 | 17.4 | 502 |

| 3806TQ | |||||||

| 18(24/32) | 6*0.75 | 0.6 | 1.1 | 0.2 | 1.3 | 13.1 | 272 |

| 16(30/30) | 6*1.5 | 0.8 | 1.3 | 0.2 | 1.6 | 16.8 | 438 |

| 14(50/30) | 6*2.5 | 0.9 | 1.4 | 0.2 | 1.8 | 19.2 | 593 |

| 3808TQ | |||||||

| 18(24/32) | 8*0.75 | 0.6 | 1.2 | 0.2 | 1.5 | 15.2 | 350 |

| 16(30/30) | 8*1.5 | 0.8 | 1.5 | 0.2 | 1.8 | 19.7 | 575 |

| 14(50/30) | 8*2.5 | 0.9 | 1.7 | 0.3 | 2.1 | 23.4 | 856 |

| 38012TQ | |||||||

| 18(24/32) | 12*0.75 | 0.6 | 1.3 | 0.2 | 1.6 | 16.8 | 449 |

| 16(30/30) | 12*1.5 | 0.8 | 1.6 | 0.3 | 2 | 22.58 | 775 |

| 14(50/30) | 12*2.5 | 0.9 | 1.8 | 0.3 | 2.3 | 26 | 1060 |

| 38016TQ | |||||||

| 18(24/32) | 16*0.75 | 0.6 | 1.4 | 0.2 | 1.7 | 18.5 | 544 |

| 16(30/30) | 16*1.5 | 0.8 | 1.8 | 0.3 | 2.2 | 25.3 | 1010 |

| 14(50/30) | 16*2.5 | 0.9 | 2 | 0.3 | 2.5 | 28.9 | 1330 |

| 38020TQ | |||||||

| 18(24/32) | 20*0.75 | 0.6 | 1.5 | 0.3 | 1.9 | 21.2 | 713 |

| 16(30/30) | 20*1.5 | 0.8 | 2.1 | 0.3 | 2.6 | 30.8 | 1430 |

| 14(50/30) | 20*2.5 | 0.9 | 2.4 | 0.4 | 3 | 36.3 | 2140 |

| 38025TQ | |||||||

| 18(24/32) | 25*0.75 | 0.6 | 1.7 | 0.3 | 2.1 | 23.6 | 866 |

| 16(30/30) | 25*1.5 | 0.8 | 2.1 | 0.3 | 2.6 | 30.8 | 1430 |

| 14(50/30) | 25*2.5 | 0.9 | 2.4 | 0.4 | 3 | 36.3 | 2140 |

| 38030TQ | |||||||

| 18(24/32) | 30*0.75 | 0.6 | 1.8 | 0.3 | 2.2 | 25 | 986 |

| 16(30/30) | 30*1.5 | 0.8 | 2.2 | 0.4 | 2.8 | 33.2 | 1760 |

| 14(50/30) | 30*2.5 | 0.9 | 2.6 | 0.4 | 3.2 | 38.7 | 2440 |