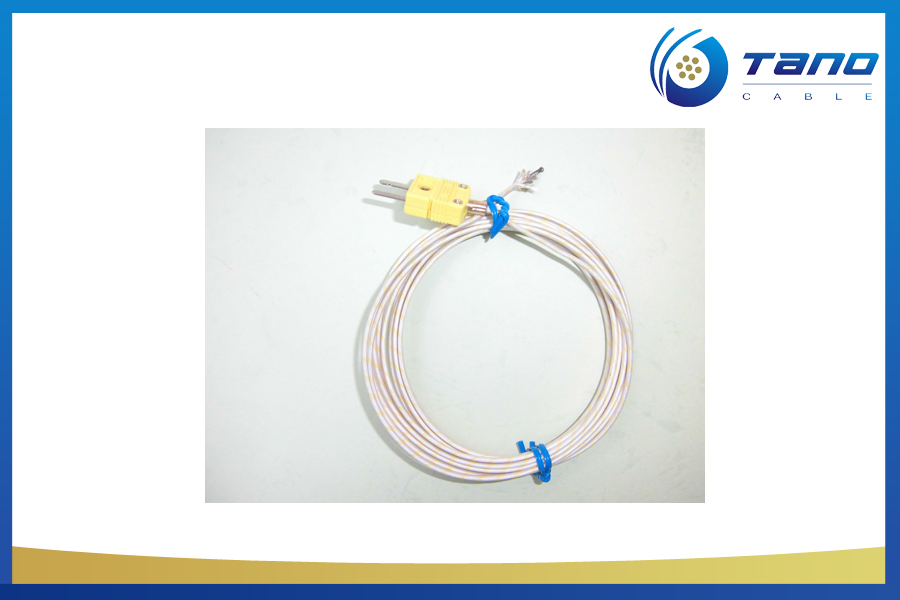

A thermocouple is composed of two wires made from dissimilar metals. These two wires are joined to form a temperature measurement junction. Each wire is made of a specific metal or metal alloy. For example, the positive (+) conductor of a type K thermocouple is made of a chromium/nickel alloy called chromel and the negative (-) conductor is made of an aluminum/nickel alloy called alumel. Wire used to make a thermocouple junction is called thermocouple wire.

Thermocouple Types

Industry specifications recognize different types of thermocouples and thermocouple wires with a letter designating each type. Some common types are K, J, T and E. Different thermocouple types have different temperature ranges over which they can be used successfully. The chemical make-up of each thermocouple alloy, the temperature error limits allowed, and the color codes for each thermocouple type are specified in ISA/ANSI standard MC96.1. The important thing to remember from an application standpoint is that the thermocouple wire type must match the thermocouple type.

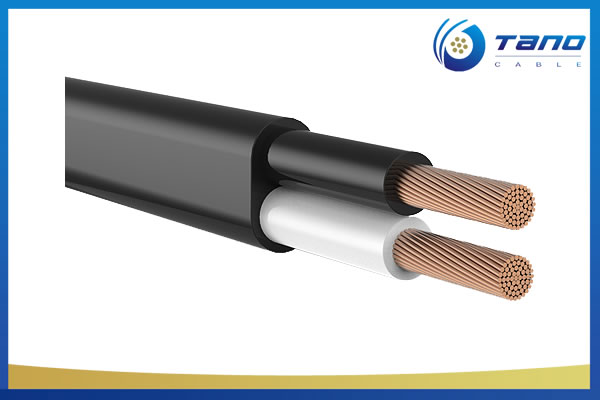

Extension Wire

Thermocouple extension wire types such as KX, JX, TX and EX are used to connect the measuring junction to the temperature recording or process control instrumentation. This can be hundreds or even thousands of feet away. Extension wire is normally exposed to temperatures and other environmental conditions that are less extreme than those encountered by the measuring junction. As a result, “extension” grade wire is not calibrated above 400° F (204° C) and is typically insulated and jacketed with materials with lower temperature ratings. Since low voltage instrumentation signals are being carried thermocouple extension wire is often shielded.

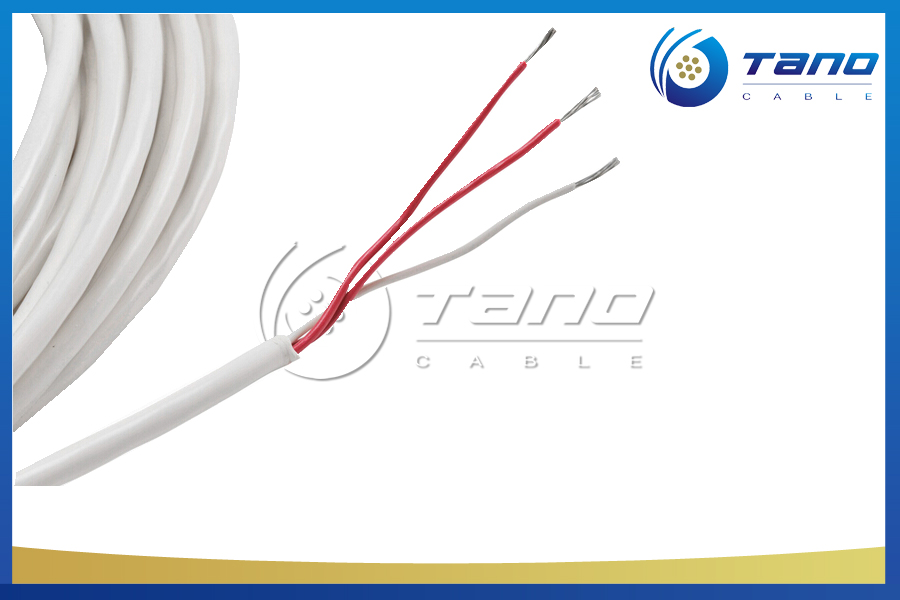

Resistance Temperature Detectors (RTDs)

There are other temperature measurement technologies than the thermocouple such as RTDs (resistance temperature detector). In applications with temperatures above 1,200° F (650° C) thermocouple is used. At lower temperatures RTDs are used for their simpler operation and greater sensitivity and stability. Thermocouples have a better response time. RTDs are special resistors whose resistance value changes with temperature in a known way. RTDs are connected to the temperature recording or process control instrumentation using ordinary copper instrumentation cable. Thermocouple wire is not required to connect an RTD.

Typical RTD cable is standard instrumentation cable in two, three, or four conductors or possibly groups of pairs/triads/quads depending on the type of RTD being used and number of devices being monitored. Individual or overall shielding is often used for noise immunity.