APPLICATION of PVC Insulation SY Push Pull Control Cable

PVC Insulation SY Push Pull Control Cable is supplied to a wide number of industries including building and construction (often in airports), rail and transport infrastructure, transmission, distribution and power networks as well as automation and process control. PVC Insulation SY Push Pull Control Cable is used as interconnecting cable for measuring, controlling or regulation in signal and control equipment. This braided control cable is found frequently on assembly and production lines, conveyors, in computer units and machine tool manufacture. The PVC Insulation SY Push Pull Control Cable’s flexible and versatile design makes it a great choice for linking fixed and mobile equipment – as well as projects where fixed installations are required. With the right protection (such as keeping it out of direct sunlight), PVC Insulation SY Push Pull Control Cable is useful for outdoor installations. The SY Flex is most suitable, however, for work in dry or moist indoor environments.

STANDARD of PVC Insulation SY Push Pull Control Cable

BS6500, VDE0250

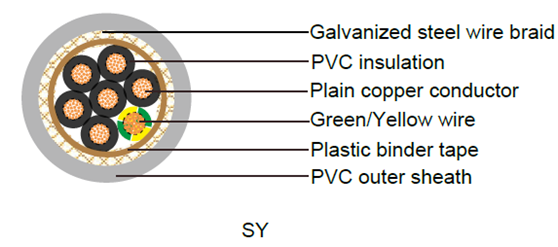

CONSTRUCTION of PVC Insulation SY Push Pull Control Cable

Plain copper conductor

Stranded to DIN VDE 0295 cl. 5, BS 6360 cl. 5 IEC 60228 cl.5

PVC core insulation type Y12

Black with White numbers

Green-yellow grounding (3 conductors and above)

PVC bedding type YM2

Galvanized Steel Wire Braid

Transparent PVC outer jacket type YM2

TECHNICAL DATA of PVC Insulation SY Push Pull Control Cable

Working voltage: 300/500 volts

Test voltage: 3000 volts

Minimum bending radius: 10 x Ø

Flexing temperature: -15º C to +70º C

Static temperature: -35º C to +70º C

Short circuit temperature: +160º C

Flame retardant: IEC 60332.3

Insulation resistance: 20 MΩ x km

CONSTRUCTION PARAMETER of PVC Insulation SY Push Pull Control Cable

|

AWG |

No. of Cores x Nominal Cross Sectional Area |

Diameter over Bedding |

Diameter Over Braid |

Nominal Overall Diameter |

Cable Weight |

|

# x mm² |

mm |

mm |

kg/km |

kg/km |

|

|

20(16/32) |

2 x 0.5 |

5.5 |

6.5 |

8.3 |

91 |

|

20(16/32) |

3 x 0.5 |

5.7 |

6.7 |

8.6 |

99 |

|

20(16/32) |

4 x 0.5 |

6.2 |

7.2 |

9.1 |

113 |

|

20(16/32) |

5 x 0.5 |

6.7 |

7.7 |

9.7 |

129 |

|

20(16/32) |

7 x 0.5 |

7.3 |

8.3 |

10.3 |

150 |

|

20(16/32) |

12 x 0.5 |

9.7 |

10.7 |

12.4 |

214 |

|

20(16/32) |

18 x 0.5 |

11.2 |

12.4 |

14.3 |

298 |

|

20(16/32) |

25 x 0.5 |

13.7 |

14.9 |

16.8 |

400 |

|

20(16/32) |

30 x 0.5 |

14.2 |

15.4 |

17.7 |

454 |

|

20(16/32) |

35 x 0.5 |

15.9 |

17.1 |

19.9 |

585 |

|

20(16/32) |

41 x 0.5 |

17.5 |

18.7 |

21.5 |

671 |

|

20(16/32) |

50 x 0.5 |

18.4 |

19.6 |

21.9 |

694 |

|

20(16/32) |

60 x 0.5 |

20 |

21.2 |

24.2 |

895 |

|

18(24/32) |

2 x 0.75 |

6.1 |

7.1 |

9 |

85 |

|

18(24/32) |

3 x 0.75 |

6.4 |

7.4 |

9.3 |

116 |

|

18(24/32) |

4 x 0.75 |

6.9 |

7.9 |

9.8 |

133 |

|

18(24/32) |

5 x 0.75 |

7.6 |

8.6 |

10.5 |

155 |

|

18(24/32) |

7 x 0.75 |

8.3 |

9.3 |

11.2 |

182 |

|

18(24/32) |

12 x 0.75 |

10.8 |

11.8 |

13.7 |

266 |

|

18(24/32) |

18 x 0.75 |

13.1 |

14.3 |

16.2 |

388 |

|

18(24/32) |

25 x 0.75 |

15.6 |

16.8 |

19.1 |

521 |

|

18(24/32) |

30 x 0.75 |

16.1 |

17.3 |

19.6 |

572 |

|

18(24/32) |

35 x 0.75 |

17.9 |

19.1 |

21.4 |

684 |

|

18(24/32) |

50 x 0.75 |

20.9 |

22.1 |

24.8 |

909 |

|

18(24/32) |

60 x 0.75 |

22.3 |

23.8 |

26.4 |

1050 |

|

17(32/32) |

2 x 1.0 |

6.3 |

7.3 |

9.3 |

101 |

|

17(32/32) |

3 x 1.0 |

6.6 |

7.6 |

9.5 |

126 |

|

17(32/32) |

4 x 1.0 |

7.2 |

8.2 |

10.1 |

146 |

|

17(32/32) |

5 x 1.0 |

7.9 |

8.9 |

10.8 |

171 |

|

17(32/32) |

7 x 1.0 |

8.6 |

9.6 |

11.5 |

203 |

|

17(32/32) |

12 x 1.0 |

11.2 |

12.4 |

14.3 |

314 |

|

17(32/32) |

18 x 1.0 |

13.6 |

14.8 |

16.7 |

441 |

|

17(32/32) |

25 x 1.0 |

16.2 |

17.4 |

19.7 |

594 |

|

17(32/32) |

30 x 1.0 |

16.8 |

18 |

20.3 |

658 |

|

17(32/32) |

35 x 1.0 |

18.6 |

19.8 |

22.1 |

786 |

|

17(32/32) |

50 x 1.0 |

21.8 |

23.3 |

25.9 |

1070 |

|

17(32/32) |

60 x 1.0 |

23.6 |

25.1 |

27.7 |

1240 |

|

16(30/30) |

2 x 1.5 |

6.8 |

7.8 |

9.8 |

114 |

|

16(30/30) |

3 x 1.5 |

7.2 |

8.2 |

10.1 |

145 |

|

16(30/30) |

4 x 1.5 |

7.9 |

8.9 |

10.8 |

171 |

|

16(30/30) |

5 x 1.5 |

8.7 |

9.7 |

11.6 |

202 |

|

16(30/30) |

7 x 1.5 |

9.5 |

10.5 |

12.4 |

242 |

|

16(30/30) |

12 x 1.5 |

12.8 |

14 |

15.9 |

394 |

|

16(30/30) |

18 x 1.5 |

15.1 |

16.3 |

18.6 |

553 |

|

16(30/30) |

25 x 1.5 |

18.4 |

19.6 |

21.9 |

746 |

|

16(30/30) |

30 x 1.5 |

19.1 |

20.3 |

23 |

850 |

|

16(30/30) |

35 x 1.5 |

20.7 |

21.9 |

24.6 |

990 |

|

16(30/30) |

50 x 1.5 |

24.7 |

26.2 |

29.2 |

1380 |

|

16(30/30) |

60 x 1.5 |

26.3 |

27.8 |

30.8 |

1570 |

|

14(30/50) |

2 x 2.5 |

8 |

9 |

11 |

143 |

|

14(30/50) |

3 x 2.5 |

8.5 |

9.5 |

11.4 |

193 |

|

14(30/50) |

4 x 2.5 |

9.4 |

10.4 |

12.3 |

232 |

|

14(30/50) |

5 x 2.5 |

10.3 |

11.3 |

13.2 |

277 |

|

14(30/50) |

7 x 2.5 |

11.3 |

12.5 |

14.4 |

353 |

|

14(30/50) |

12 x 2.5 |

15.3 |

16.5 |

18.8 |

575 |

|

14(30/50) |

18 x 2.5 |

18.5 |

19.7 |

22 |

818 |

|

14(30/50) |

25 x 2.5 |

22.1 |

23.6 |

26.2 |

1130 |

|

14(30/50) |

30 x 2.5 |

23.4 |

24.9 |

27.5 |

1290 |

|

14(30/50) |

35 x 2.5 |

25.3 |

26.8 |

29.8 |

1540 |

|

14(30/50) |

50 x 2.5 |

29.8 |

31.3 |

34.7 |

2060 |

|

14(30/50) |

60 x 2.5 |

31.7 |

33.2 |

36.6 |

2350 |

|

12(56/28) |

3 x 4.0 |

11.5 |

12.8 |

14.8 |

312 |

|

12(56/28) |

4 x 4.0 |

12.7 |

13.9 |

15.8 |

384 |

|

12(56/28) |

5 x 4.0 |

14 |

15.2 |

17.5 |

478 |

|

12(56/28) |

7 x 4.0 |

15.3 |

16.5 |

18.8 |

587 |

|

10(84/28) |

2 x 6.0 |

12.2 |

13.4 |

15.4 |

316 |

|

10(84/28) |

3 x 6.0 |

13 |

14.2 |

16.2 |

407 |

|

10(84/28) |

4 x 6.0 |

14.4 |

15.6 |

17.9 |

508 |

|

10(84/28) |

5 x 6.0 |

15.9 |

17.1 |

19.4 |

617 |

|

10(84/28) |

7 x 6.0 |

17.9 |

19.1 |

21.4 |

789 |

|

8(80/26) |

2 x 10.0 |

15.3 |

16.5 |

18.9 |

467 |

|

8(80/26) |

3 x 10.0 |

16.5 |

17.7 |

20.1 |

621 |

|

8(80/26) |

4 x 10.0 |

18.4 |

19.6 |

21.9 |

779 |

|

8(80/26) |

5 x 10.0 |

20.4 |

21.6 |

24.3 |

978 |

|

8(80/26) |

7 x 10.0 |

22.4 |

23.9 |

26.5 |

1250 |

|

6(128/26) |

3 x 16.0 |

19.7 |

20.8 |

23.8 |

857 |

|

6(128/26) |

4 x 16.0 |

21.4 |

22.7 |

25.5 |

1040 |

|

6(128/26) |

5 x 16.0 |

24.1 |

25.4 |

28.6 |

1300 |

|

4(200/26) |

3 x 25.0 |

21.4 |

22.7 |

25.5 |

1110 |

|

4(200/26) |

4 x 25.0 |

23.8 |

25.1 |

27.2 |

1350 |

|

4(200/26) |

5 x 25.0 |

26.4 |

27.7 |

31.3 |

1740 |

|

4(200/26) |

5 x 35.0 |

- |

- |

36 |

3185 |