APPLICATION of CY LSZH Screened Control Cable VDE

CY LSZH Screened Control Cable is used as interconnecting cable for measuring, controlling or regulation in control equipment for assembly and production lines, conveyors and for computer units. CY LSZH Screened Control Cable is suitable for fixed installations or for flexible use when temporarily moved, and in conditions of medium mechanical stress. For installation where fire, smoke emission and toxic fumes create a potential threat to life and equipment. Can be used outdoors when protected, and in dry or moist conditions indoors.

STANDARD of CY LSZH Screened Control Cable VDE

BS6500, VDE0250, IEC 60332-3, IEC 60754-1

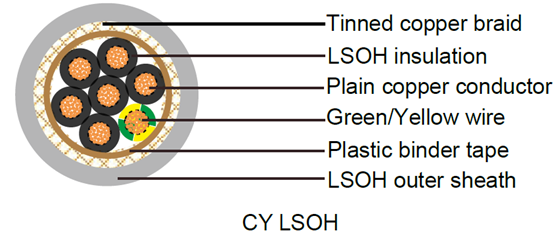

CONSTRUCTION of CY LSZH Screened Control Cable VDE

Plain copper conductor

Stranded to DIN VDE 0295 cl. 5, BS 6360 cl. 5 IEC 60228 cl.5

LSOH core insulation H12- DIN VDE 027 PT23

Color coded to VDE-0293-308

Green-yellow grounding (3 conductors and above)

Plastic binder tape

Tinned Copper Wire Braid Screen

LSOH outer jacket

TECHNICAL DATA of CY LSZH Screened Control Cable VDE

Working voltage: 300/500 volts

Test voltage: 2000 volts

Minimum bending radius: 10 x Ø

Flexing temperature: -15º C to +70º C

Static temperature: -35º C to +70º C

Short circuit temperature: +160º C

Flame retardant: IEC 60332.3

Insulation resistance: 20 MΩ x km

CONSTRUCTION PARAMETER of CY LSZH Screened Control Cable VDE

|

AWG |

No. of Cores |

|

|

|

|

x Nominal |

Nominal |

Nominal |

Nominal |

|

|

Cross |

Overall |

Copper |

Cable |

|

|

Sectional |

Diameter |

Weight |

Weight |

|

|

Area |

|

|

|

|

|

|

No. xmm2 |

mm |

kg/km |

kg/km |

|

20(16/32) |

2 x0.5 |

7 |

35 |

80 |

|

20(16/32) |

3 x0.5 |

7.3 |

45.5 |

106 |

|

20(16/32) |

4 x0.5 |

7.9 |

55.2 |

123 |

|

20(16/32) |

5G0.5 |

8.4 |

66 |

134 |

|

20(16/32) |

7G0.5 |

9.9 |

80.5 |

160 |

|

20(16/32) |

12G0.5 |

11.3 |

138.5 |

237 |

|

18(24/32) |

2 x0.75 |

7.4 |

45 |

115 |

|

18(24/32) |

3 x0.75 |

7.9 |

57.9 |

125 |

|

18(24/32) |

4 x0.75 |

8.4 |

64 |

141 |

|

18(24/32) |

5 x0.75 |

8.9 |

77.4 |

162 |

|

18(24/32) |

7 x0.75 |

10.6 |

102 |

187 |

|

18(24/32) |

12G0.75 |

12.3 |

177 |

313 |

|

18(24/32) |

18G0.75 |

14.5 |

243 |

456 |

|

18(24/32) |

25G0.75 |

16.6 |

307.3 |

575 |

|

17(32/32) |

2 x1.0 |

7.9 |

50 |

127 |

|

17(32/32) |

3 x1.0 |

8.2 |

65.3 |

140 |

|

17(32/32) |

4 x1.0 |

8.7 |

78.1 |

160 |

|

17(32/32) |

5G1.0 |

9.5 |

89.4 |

182 |

|

17(32/32) |

7G1.0 |

10.8 |

113.6 |

215 |

|

17(32/32) |

12G1.0 |

13.3 |

188.1 |

352 |

|

17(32/32) |

18G1.0 |

15.5 |

286 |

514 |

|

17(32/32) |

25G1.0 |

17.5 |

388.5 |

677 |

|

17(32/32) |

41G1.0 |

22 |

578 |

1010 |

|

16(30/30) |

2 x1.5 |

8.5 |

77 |

172 |

|

16(30/30) |

3 x1.5 |

8.9 |

83 |

187 |

|

16(30/30) |

4G1.5 |

9.6 |

100 |

201 |

|

16(30/30) |

5G1.5 |

10.3 |

125 |

231 |

|

16(30/30) |

7G1.5 |

13.1 |

196 |

310 |

|

16(30/30) |

12G1.5 |

14.8 |

280 |

505 |

|

16(30/30) |

18G1.5 |

17.2 |

389 |

671 |

|

16(30/30) |

25G1.5 |

20.1 |

535 |

955 |

|

14(30/50) |

3G2.5 |

10.3 |

146 |

211 |

|

14(30/50) |

4G2.5 |

11.3 |

167 |

356 |

|

14(30/50) |

5G2.5 |

12.6 |

200.2 |

386 |

|

14(30/50) |

7G2.5 |

13.9 |

288 |

498 |

|

14(30/50) |

12G2.5 |

17.6 |

477.3 |

911 |

|

12(56/28) |

4G4 |

13.4 |

237 |

458 |

|

12(56/28) |

5G4 |

14.7 |

280 |

532 |

|

12(56/28) |

7G4 |

18.2 |

388 |

766 |

|

10(84/28) |

4G6 |

15.8 |

318 |

611 |

|

10(84/28) |

5G6 |

17.3 |

453 |

770 |

|

10(84/28) |

7G6 |

24.8 |

524.7 |

1035 |

|

8(80/26) |

4G10 |

24.4 |

558 |

986 |

|

6(128/26) |

4G16 |

24.4 |

558 |

986 |

|

4(200/26) |

4G25 |

32.9 |

1289 |

2028 |

|

2(280/26) |

4G35 |

36.8 |

1693 |

2649 |

|

1(400/26) |

4G50 |

42.4 |

2342 |

3741 |

|

2/0(356/24) |

4G70 |

49.4 |

3035 |

5054 |

|

3/0(485/24 |

4G95 |

54.5 |

4055 |

6427 |