APPLICATION of LIYCY TP twist control cable VDE standard

LIYCY TP twist control cable VDE standard is used for flexible use with free movement, but without tensile stress or forced movements in dry, wet and moist areas but are not suitable for open air application. LIYCY TP twist control cable is commonly used as control and signal cable in the electronics of computer systems, electronic control equipment, office machines and measurement devices in the tool making and machine industries. The twisted pair construction reduces interference (crosstalk) within the cable while the tinned copper braid shield offers optimum protection from electrical and electromagnetic interference.

STANDARD of LIYCY TP twist control cable VDE standard

VDE 0812, VDE 0814, CE Low Voltage Directive 73/23/EEC and 93/68/EEC, ROHS compliant

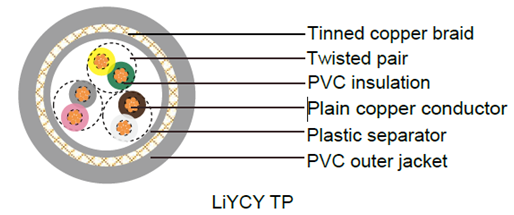

CONSTRUCTION of LIYCY TP twist control cable VDE standard

Plain copper conductor

Stranded to DIN VDE 0295 cl. 5, BS 6360 cl. 5 IEC 60228 cl.5

PVC core insulation to DIN VDE 0281 part 1

Color coded to DIN 47100, but without color repetition

Cores twisted into layers

Plastic foil separator

85% tinned copper braid

PVC outer jacket to DIN VDE 0281 part 1

TECHNICAL DATA of LIYCY TP twist control cable VDE standard

Working voltage: 250 volts

Test voltage: 1200 volts

Minimum bending radius: 5 x Ø

Flexing temperature: -5º C to +70º C

Static temperature: -30º C to +70º C

Flame retardant: IEC 60332.1

Insulation resistance: 20 MΩ x km

CONSTRUCTION PARAMETER of LIYCY TP twist control cable VDE standard

|

AWG |

No. of Cores x Nominal Cross Sectional Area |

Nominal Overall Diameter |

Copper Weight |

Cable Weight |

|

No. x mm² |

mm |

kg/km |

kg/km |

|

|

26(18/38) |

2 x 2 x 0.14 |

5.2 |

18.5 |

40 |

|

26(18/38) |

3 x 2 x 0.14 |

5.6 |

23 |

49 |

|

26(18/38) |

4 x 2 x 0.14 |

5.8 |

26.6 |

55 |

|

26(18/38) |

5 x 2 x 0.14 |

6.5 |

30.7 |

66 |

|

26(18/38) |

6 x 2 x 0.14 |

7.3 |

48.5 |

86 |

|

26(18/38) |

7 x 2 x 0.14 |

7.5 |

51.1 |

91 |

|

26(18/38) |

8 x 2 x 0.14 |

7.8 |

53.7 |

97 |

|

26(18/38) |

10 x 2 x 0.14 |

8.5 |

59 |

109 |

|

26(18/38) |

12 x 2 x 0.14 |

9.3 |

66 |

141 |

|

26(18/38) |

14 x 2 x 0.14 |

10 |

74 |

148 |

|

26(18/38) |

15 x 2 x 0.14 |

10.3 |

76 |

152 |

|

26(18/38) |

16 x 2 x 0.14 |

10.7 |

79 |

155 |

|

26(18/38) |

18 x 2 x 0.14 |

11 |

83 |

171 |

|

26(18/38) |

20 x 2 x 0.14 |

11.2 |

97 |

183 |

|

26(18/38) |

22 x 2 x 0.14 |

11.6 |

103 |

205 |

|

26(18/38) |

24 x 2 x 0.14 |

12 |

111 |

228 |

|

26(18/38) |

25 x 2 x 0.14 |

12.4 |

113 |

239 |

|

26(18/38) |

26 x 2 x 0.14 |

12.8 |

122 |

245 |

|

26(18/38) |

27 x 2 x 0.14 |

13 |

125 |

251 |

|

26(18/38) |

28 x 2 x 0.14 |

13.2 |

128 |

258 |

|

26(18/38) |

30 x 2 x 0.14 |

13.6 |

140 |

270 |

|

26(18/38) |

32 x 2 x 0.14 |

14.2 |

145 |

284 |

|

26(18/38) |

34 x 2 x 0.14 |

14.6 |

150 |

300 |

|

26(18/38) |

36 x 2 x 0.14 |

14.8 |

156 |

316 |

|

26(18/38) |

38 x 2 x 0.14 |

15 |

162 |

350 |

|

26(18/38) |

40 x 2 x 0.14 |

15.4 |

177 |

370 |

|

26(18/38) |

44 x 2 x 0.14 |

16 |

181 |

390 |

|

26(18/38) |

46 x 2 x 0.14 |

16.4 |

195 |

430 |

|

26(18/38) |

50 x 2 x 0.14 |

17.8 |

202 |

440 |

|

26(18/38) |

52 x 2 x 0.14 |

18 |

206 |

460 |

|

26(18/38) |

55 x 2 x 0.14 |

18.8 |

210 |

480 |

|

24(14/34) |

2 x 2 x 0.25 |

6.3 |

28 |

53 |

|

24(14/34) |

3 x 2 x 0.25 |

6.7 |

32 |

65 |

|

24(14/34) |

4 x 2 x 0.25 |

6.8 |

38 |

80 |

|

24(14/34) |

5 x 2 x 0.25 |

7.8 |

55 |

98 |

|

24(14/34) |

6 x 2 x 0.25 |

8.8 |

65 |

114 |

|

24(14/34) |

7 x 2 x 0.25 |

8.9 |

70 |

121 |

|

24(14/34) |

8 x 2 x 0.25 |

9.6 |

75 |

129 |

|

24(14/34) |

10 x 2 x 0.25 |

10.6 |

110 |

157 |

|

24(14/34) |

12 x 2 x 0.25 |

11.6 |

117 |

189 |

|

24(14/34) |

14 x 2 x 0.25 |

12 |

122 |

213 |

|

24(14/34) |

15 x 2 x 0.25 |

12.5 |

134 |

225 |

|

24(14/34) |

16 x 2 x 0.25 |

13 |

143 |

237 |

|

24(14/34) |

18 x 2 x 0.25 |

13.2 |

148 |

248 |

|

24(14/34) |

20 x 2 x 0.25 |

13.7 |

162 |

275 |

|

24(14/34) |

22 x 2 x 0.25 |

14.4 |

172 |

303 |

|

24(14/34) |

24 x 2 x 0.25 |

15 |

223 |

330 |

|

24(14/34) |

25 x 2 x 0.25 |

15.4 |

233 |

343 |

|

24(14/34) |

26 x 2 x 0.25 |

15.8 |

238 |

345 |

|

24(14/34) |

27 x 2 x 0.25 |

16.2 |

244 |

350 |

|

24(14/34) |

28 x 2 x 0.25 |

16.3 |

249 |

360 |

|

24(14/34) |

30 x 2 x 0.25 |

16.7 |

254 |

375 |