APPLICATION OF VDE STANDARD MV 3 CORE 50MM POWER CABLE

The three core MV power cable are designed for distribution of electrical power with nominal voltage Uo/U ranging from 3.6/6.6KV to 19/33KV and frequency 50Hz. They are suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground and in water as well as for installation on cable trays for industries, switchboards and power stations.

STANDARD OF VDE STANDARD MV 3 CORE 50MM POWER CABLE

DIN VDE 0276 Part 620 -622

HD 620 S1.

CONSTRUCTION OF VDE STANDARD MV 3 CORE 50MM POWER CABLE

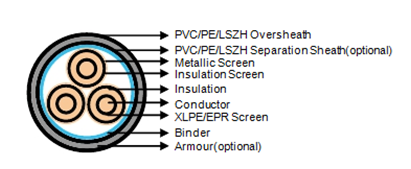

Conductor: Stranded compacted circular copper or aluminum conductors according to IEC 60228 class 2 / VDE 0276 class 2. VDE 0295 HD 383. All internal interstices of the conductor are filled with water blocking compound to prevent ingress of water through conductor during storage, handing, installation and operating of the cable.

Conductor Screen: The conductor screen consists of an extruded layer of non metallic, semi-conducting compound firmly bonded to the insulation to exclude all air voids. The screen has a minimum thickness of 0.3mm and the maximum volume resistivity of 500 Ohm-m at 90°C.

Insulation: Insulation is of extruded XLPE compound type 2XI1 according to DIN VDE 0207 part 22 and HD 620.1 with high degree of cross-linking, free from contaminants, air voids and heat resistant by dry cured process. The nominal insulation wall thickness is shown in table 1.

Table 1. Insulation Thickness

|

Nom. Cross-Section |

Insulation Thickness at Nom. Voltage |

||||

|

Area |

3.6/6kV |

6/10KV |

8.7/15KV |

12/20KV |

18/30KV |

|

|

(Um=7.2)kV |

(Um=12KV) |

(Um=17KV) |

(Um=24KV) |

(Um=36KV) |

|

mm² |

mm |

mm |

mm |

mm |

mm |

|

|

XLPE |

XLPE |

XLPE |

XLPE |

XLPE |

|

35 |

2.5 |

3.4 |

4.5 |

5.5 |

- |

|

50 |

2.5 |

3.4 |

4.5 |

5.5 |

8 |

|

70 |

2.5 |

3.4 |

4.5 |

5.5 |

8 |

|

95 |

2.5 |

3.4 |

4.5 |

5.5 |

8 |

|

120 |

2.5 |

3.4 |

4.5 |

5.5 |

8 |

|

150 |

2.5 |

3.4 |

4.5 |

5.5 |

8 |

|

185 |

2.5 |

3.4 |

4.5 |

5.5 |

8 |

|

240 |

2.6 |

3.4 |

4.5 |

5.5 |

8 |

|

300 |

2.8 |

3.4 |

4.5 |

5.5 |

8 |

|

400 |

3 |

3.4 |

4.5 |

5.5 |

8 |

Insulation Screen: The insulation screen consists of extruded non metallic, semi-conducting compound extruded over the insulation. The extruded semi-conducting layer shall consist of bonded or cold strippable semi-conducting compound capable of removal for jointing or terminating. The minimum thickness is 0.3mm and the maximum volume resistivity of 500 Ohm-m at 90°C. The screen is tightly fitted to the insulation to exclude all air voids and can be easily hand stripped on site.

Conducting Water Blocking Layer: The insulation screen may be covered by semi-conductive water blocking tape which will swell up under the influence of moisture of water to ensure longitudinal watertightness.

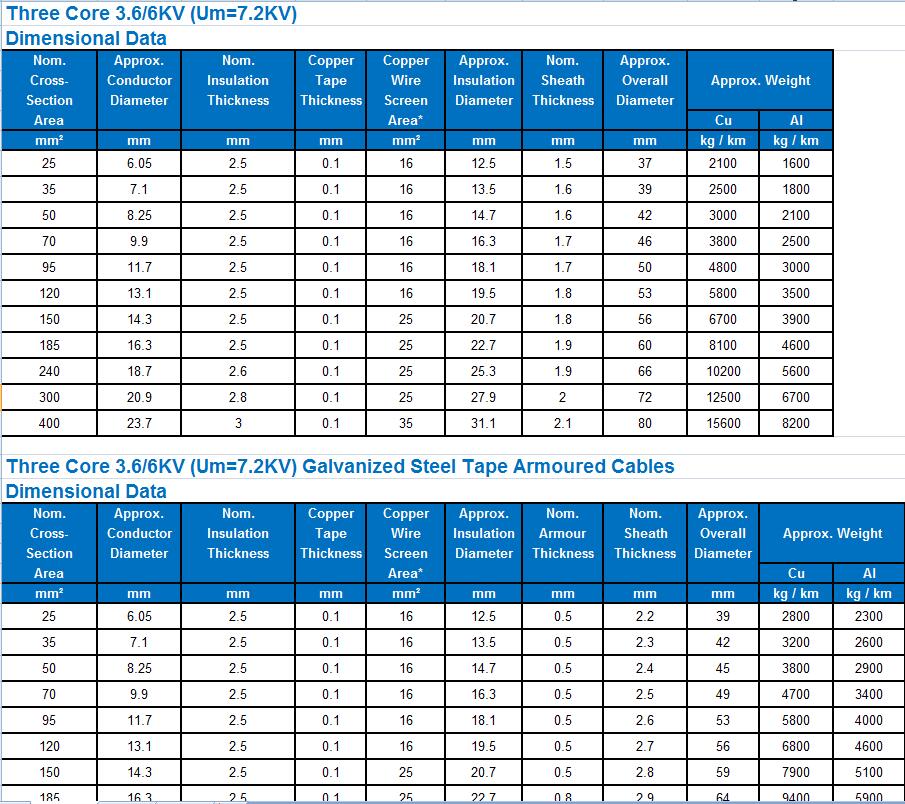

Metallic Screen: Copper wires are applied over the conducting water blocking layer with a minimum diameter of 0.5mm. And over the copper wires, copper tape with minimum thickness of 0.1mm is applied helically with overlap. Total cross section of metallic screen layer is shown in table 2. The screen can withstand of fault current to earth of 1000 A for one second at maximum temperature of 160°C. Minimum cross section of concentric conductor is according to DIN VDE 0273 & 0276 as shown.

Table 2. Minimum Total Cross Section of Metallic Screen

|

Nominal Cross-Section Area Of Cable |

Minimum Cross-Section |

DC Resistance of the Copper Wire Screen |

|

of Metallic Screen |

||

|

mm² |

mm² |

mm |

|

Up to 120 |

16 |

1.06 |

|

150-300 |

25 |

0.72 |

|

400-630 |

35 |

0.51 |

|

800-1000 |

50 |

0.35 |

Separator / Water Blocking Layer: The metallic screen may be covered by non-conducting water blocking tape which will swell up under the influence of moisture of water to ensure longitudinal watertightness.

Separation Sheath (for armored cable): The separation sheath comprises a layer of extruded PVC, PE or LSZH, applied under the armor. Thickness of separation sheath is shown in table 3.

Table 3. Separation Sheath Thickness

|

Cores Diameter |

Approx.Thickess of Inner Sheath |

|

|

mm |

mm |

|

|

> |

< |

|

|

35 |

45 |

1.4 |

|

45 |

60 |

1.6 |

|

60 |

80 |

1.8 |

|

80 |

- |

2 |

Armour(for armoured cable):

The armour consists of:

1) Double layers of galvanized steel tape are applied helically with proper inner overlapping over an extruded separation sheath. Thickness of the steel tape is shown in table 4.

Table 4. Galvanized Steel Tape Thickness

|

Inner Diameter |

Thickness of Galvanized Steel Tape |

|

|

mm |

mm |

|

|

> |

< |

|

|

- |

30 |

0.2 |

|

30 |

70 |

0.5 |

|

70 |

- |

0.8 |

2) Galvanized flat steel wires with thickness of 0.8 mm are applied helically over the surface of inner sheath with minimum of 90% coverage. And galvanized Steel tape with nominal thickness of 0.3 mm is applied helically with 50% coverage to cover the surface of the flat wires.

Outer Sheath: Overall sheath comprises a layer of extruded PE compound DMP2 according to HD620.1 and 2YM3 type to DIN VDE 0276 Part 3, or PVC compound DMV6 according to HD620.1 and YM5 to DIN VDE 0276 Part 6. Normal wall thickness is 2.5mm (1/500mm 18/30sq 2.6mm), suitable for exposure to sun-light or other local atmospheric environments and for the operating temperature of the cable.

PHYSICAL PROPERTIES OF VDE STANDARD MV 3 CORE 50MM POWER CABLE

Operating Temperature: up to 90°C

Temperature Range: -5°C ( PVC sheath ); -20°C ( PE sheath )

Short Circuit Temperature: 250°C (short circuit duration up to 5 seconds)

Bending Radius: 15 x OD (Cable without metal sheath)

30 x OD (Cable with aluminium sheath)

Table 5. Nominal /Operating /Testing Voltages

|

Nominal Voltage Uo/U |

Operating Voltage (Um) |

Testing Voltage |

|

3.6/6KV |

8KV |

12.5KV |

|

6/10KV |

12KV |

21KV |

|

8.7/15KV |

18KV |

30.5KV |

|

12/20KV |

24KV |

42KV |

|

18/30KV |

36KV |

63KV |

TYPE CODES OF VDE STANDARD MV 3 CORE 50MM POWER CABLE

Conductor

N According to VDE Standard (No abbreviation for copper conductor)

A Aluminum conductor

- Copper conductor

Insulation

2X XLPE

Screen

C Concentric conductor of copper

CE Concentric conductor of copper over each individual core

S Screen of copper wires & copper tape, helically wound

SE Screen of copper wires over each individual cores

(G) Longitudinally waterproof

Armour

F Armour of galvanized flat steel wire

G Counter Helix of galvanized steel tape

B Steel tape armouring

R Armour of galvanized round steel wire

Sheath

2Y PE

Y PVC

H LSZH

K Lead sheath

KL Aluminum sheath

TECHNICAL DATA OF VDE STANDARD MV 3 CORE 50MM POWER CABLE

Service Life: 30years