Electrical functions

● Equipotential screen

● Capacitive current collection/draining

● Short-circuit draining

Protection functions

● Water barrier

● Mechanical protection

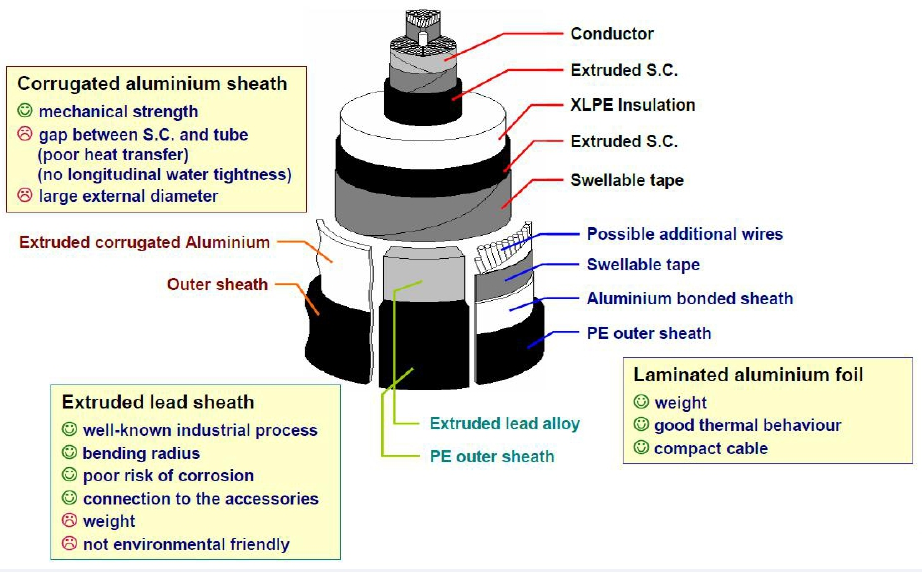

Design of the metallic screen / sheath

Main designs for HV cables

● To provide moiture barrier function

■ Extruded sheath

♦ Lead sheath

♦ Aluminium corrugated sheath

■ Longitudinally welded corrugated sheath

♦ Aluminium sheath

■ Longitudinal tape (laminated foil)

♦ Copper or aluminium

♦ Stuck with overlap or seam welded

●To provide short-circuit draining (but not

watertight)

■ Copper helically lapped tapes

■ Concentric wires

♦ Copper or Aluminium

Typical solutions

● Lead sheath

● Aluminium corrugated sheath

● Aluminium laminated foil

Possibility to combine concentric wires

● For large short-circuit currents

Main features of the typical solutions

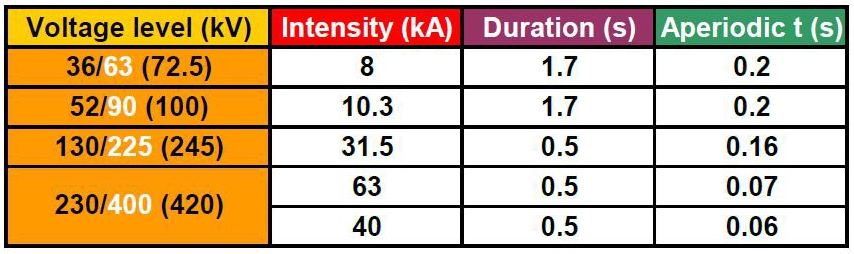

HV short-circuit data

Short-circuit test

● 3 shots

♦ 1st: conductor temperature = 90+/-4°C

♦ 2nd and 3rd = 80+/- 4°C

● Visual inspection between shots

♦ No test loop damage, especially at connections

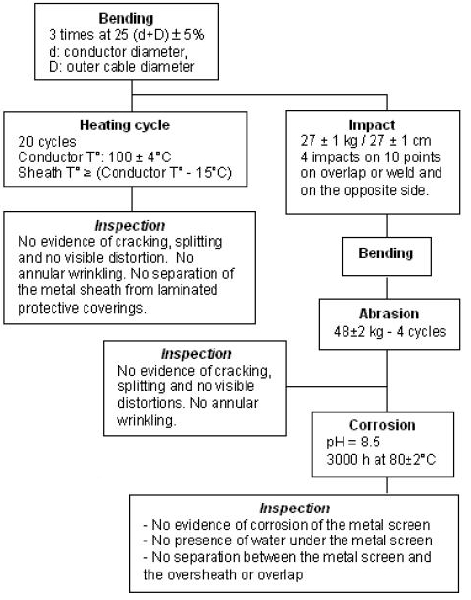

Specific tests

A primary set of tests

● to assess the watertightness of cable designs after exposure to mechanical stress

Others tests to assess

● mechanical properties only

♦ impact test and abrasion test

● radial watertightness after shrinkage

● radial watertightness after short circuits

Long term test

●200 m loop of cable with accessories

♦ 1.7 U0, 6000 hours / 250 thermal cycles

.jpg)

.jpg)

.jpg)

.jpg)