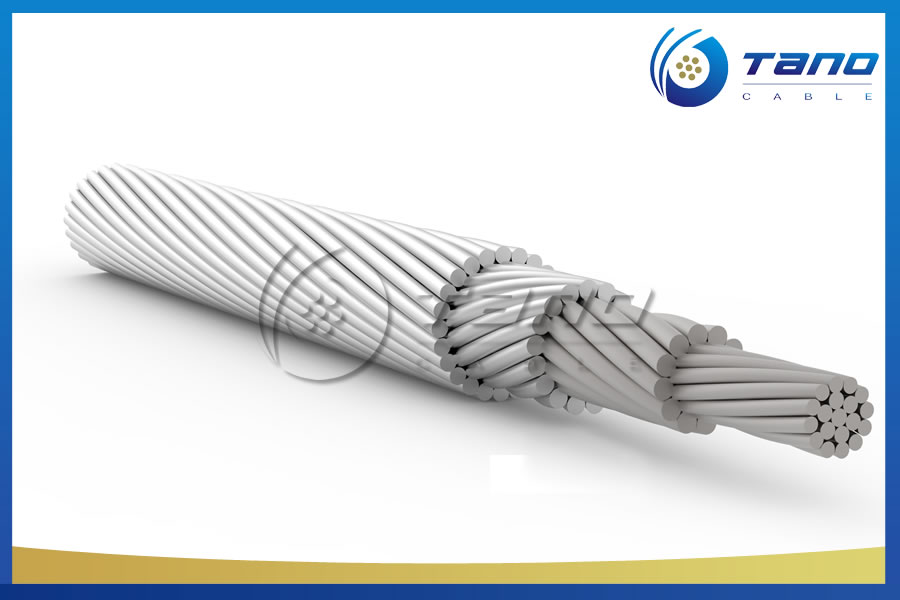

AAC conductor is also known as aluminium stranded conductor. It is manufactured from electrolytically refined aluminium, with a minimum purity of 99.7%.

STANDARD

Basic design to DIN 48201-5 standard.

CONSTRUCTION

Concentric lay stranded Aluminium Conductor ( AAC) is made up of one or more strands of hard drawn 1350 aluminum alloy. These conductors are used in low, medium and high voltage overhead lines. AAC has seen extensive use in urban areas where spans are usually short but high conductivity us required. The excellent corrosion resistance of aluminium has made AAC a conductor of choice in coastal areas. Because of its relatively poor strength to weight ratio, AAC had limited use in transmission lines and rural distribution because of long spans utilized. All aluminium conductors are made up of one or more strands of aluminium wire dep.

ELECTRICAL PROPERTIES

| Density@20ºC | 2.703 kg/dm |

| Temperature Coefficient@20°C | 0.00403 (°C) |

| Resistivity@20°C | 0.028264 |

| Linear Expansivity | 23 x10 (°C)-6 |

SERVICE CONDITIONS

| Ambient Temperature | -5°C - 50°C |

| Wind Pressure | 80 – 130kg/m2 |

| Seismic Acceleration | 0.12 - 0.05g |

| Isokeraunic Level | 10 – 18 |

| Relative Humidity | 5 – 100% |

CONSTRUCTION PARAMETER

| Nominal Area | Stranding | Overall | Weight | Rated | Electrical | Current | |

| Nominal |

Calculated

|

Diameter | Strength | Resistance | Rating* | ||

| mm2 | mm2 | No.×mm | mm | kg/km | KN | Ω/Km | A |

| 16 | 15.89 | 7/1.70 | 5.1 | 43 | 2.84 | 1.8022 | 83 |

| 25 | 24.25 | 7/2.10 | 6.3 | 66 | 4.17 | 1.181 | 108 |

| 35 | 34.36 | 7/2.50 | 7.5 | 94 | 5.78 | 0.8333 | 134 |

| 50 | 49.48 | 7/3.00 | 9 | 135 | 7.94 | 0.5787 | 168 |

| 50 | 48.35 | 19/1.80 | 9 | 133 | 8.45 | 0.5951 | 166 |

| 70 | 65.81 | 19/2.10 | 10.5 | 181 | 11.32 | 0.4372 | 200 |

| 95 | 93.27 | 19/2.50 | 12.5 | 256 | 15.68 | 0.3085 | 248 |

| 120 | 116.99 | 19/2.80 | 14 | 322 | 18.78 | 0.2459 | 285 |

| 150 | 147.11 | 37/2.25 | 15.8 | 406 | 25.3 | 0.196 | 328 |

| 185 | 181.62 | 37/2.50 | 17.5 | 500 | 30.54 | 0.1588 | 373 |

| 240 | 242.54 | 61/2.25 | 20.3 | 670 | 39.51 | 0.1191 | 445 |

| 300 | 299.43 | 61/2.50 | 22.5 | 827 | 47.7 | 0.0965 | 506 |

| 400 | 400.14 | 61/2.89 | 26 | 1104 | 60.86 | 0.0722 | 602 |

| 500 | 499.83 | 61/3.23 | 29.1 | 1379 | 74.67 | 0.0578 | 688 |

| 625* | 626.2 | 91/2.96 | 32.6 | 1732 | 95.25 | 0.0462 | 786 |

| 800* | 802.09 | 91/3.35 | 36.9 | 2218 | 118.39 | 0.036 | 907 |

| 1000* | 999.71 | 91/3.74 | 41.1 | 2767 | 145.76 | 0.0289 | 1026 |

TECHNICAL DATA

| Numbers of Wires | Final modules of Elasticity | Coefficient of Linear Expansion | ||

| Al | Kg/mm2 | lb/in2 | 1/Cº | 1/Fº |

| 7 | 6000 | 8.5 x106 | 23.0 x10-6 | 112.8 x10-6 |

| 19 | 5700 | 8.1 x106 | 23.0 x10-6 | 112.8 x10-6 |

| 37 | 5700 | 8.1 x106 | 23.0 x10-6 | 112.8 x10-6 |

| 61 | 5500 | 7.8 x106 | 23.0 x10-6 | 112.8 x10-6 |

| 91 | 5500 | 7.8 x106 | 23.0 x10-6 | 112.8 x10-6 |