APPLICATION of Building Electrical Copper Wires THW/THW-2

Building Electrical Copper Wires THW/THW-2 conductor is suitable for most current wiring solutions for residential, commercial and industrial environments. It is used in service entrance, feeders and branch circuits for permanent installations. THW conductors in sizes 14 AWG to 1000 Kcmil (MCM) can be installed in conduits and other raceways. The temperature of installation shall not exceed 75°C (THW), not exceed 90°C (THW-2).

STANDARD of Building Electrical Copper Wires THW/THW-2

ASTM: B3, B8.

UL 83 - Thermoplastic-Insulated Wires and Cables

UL 1581 - Electrical Wires, Cables and Flexible Cords

CONSTRUCTION of Building Electrical Copper Wires THW/THW-2

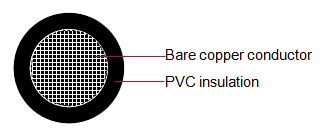

Conductor: Bare annealed copper conductor, solid or stranded

Insulation: PVC 75°C insulation

Color: upon request, black is preferable

CONSTRUCTION PARAMETER of Building Electrical Copper Wires THW/THW-2

|

AWG |

Strand |

Nominal Insulation |

Nominal Overall |

Cable |

|||

|

or |

Thickness |

Diameter |

Weight |

||||

|

Inch/mm |

Inch |

mm |

Lbs/kft |

kg/km |

Lbs/kft |

kg/km |

|

|

14 |

1 |

0.03 |

0.76 |

0.169 |

4.3 |

22 |

33 |

|

12 |

1 |

0.03 |

0.76 |

0.189 |

4.8 |

32 |

47 |

|

10 |

1 |

0.03 |

0.76 |

0.213 |

5.4 |

46 |

68 |

|

8 |

1 |

0.045 |

1.14 |

0.24 |

6.1 |

67 |

100 |

|

6 |

1 |

0.06 |

1.52 |

0.276 |

7 |

101 |

151 |

|

14 |

7 |

0.03 |

0.76 |

0.177 |

4.5 |

24 |

36 |

|

12 |

7 |

0.03 |

0.76 |

0.201 |

5.1 |

34 |

50 |

|

10 |

7 |

0.03 |

0.76 |

0.228 |

5.8 |

49 |

73 |

|

8 |

7 |

0.045 |

1.14 |

0.291 |

7.4 |

79 |

118 |

|

6 |

7 |

0.06 |

1.52 |

0.335 |

8.5 |

117 |

174 |

|

4 |

7 |

0.06 |

1.52 |

0.386 |

9.8 |

172 |

256 |

|

2 |

7 |

0.08 |

2.03 |

0.445 |

11.3 |

263 |

391 |

|

1 |

19 |

0.08 |

2.03 |

0.531 |

13.5 |

339 |

505 |

|

1/0 |

19 |

0.08 |

2.03 |

0.575 |

14.6 |

418 |

622 |

|

2/0 |

19 |

0.08 |

2.03 |

0.622 |

15.8 |

515 |

767 |

|

3/0 |

19 |

0.08 |

2.03 |

0.677 |

17.2 |

638 |

950 |

|

4/0 |

37 |

0.08 |

2.03 |

0.74 |

18.8 |

792 |

1179 |

|

250 |

37 |

0.095 |

2.41 |

0.823 |

20.9 |

943 |

1404 |

|

300 |

37 |

0.095 |

2.41 |

0.882 |

22.4 |

1118 |

1664 |

|

350 |

37 |

0.095 |

2.41 |

0.937 |

23.8 |

1292 |

1923 |

|

400 |

37 |

0.095 |

2.41 |

0.984 |

25 |

1465 |

2180 |

|

500 |

61 |

0.095 |

2.41 |

1.079 |

27.4 |

1810 |

2694 |

|

600 |

61 |

0.11 |

2.79 |

1.197 |

30.4 |

2178 |

3241 |

|

700 |

61 |

0.11 |

2.79 |

1.272 |

32.3 |

2521 |

3751 |

|

750 |

61 |

0.11 |

2.79 |

1.307 |

33.2 |

2693 |

4007 |

|

800 |

61 |

0.11 |

2.79 |

1.343 |

34.1 |

2863 |

4260 |

|

900 |

61 |

0.11 |

2.79 |

1.409 |

35.8 |

3205 |

4769 |

|

1000 |

61 |

0.11 |

2.79 |

1.472 |

37.4 |

3538 |

5265 |