APPLICATION of 600V 8 AWG THHN/THWN building wire

600V 8 AWG THHN/THWN electric wire building wire conductors are primarily used in conduit for services, feeder, and branch circuits in commercial or industrial applications as specified in the National Electrical Code.

When used as 600V 8 AWG THHN, conductor is suitable for use in dry locations at temperatures not to exceed 90°C.

When used as 600V 8 AWG THWN, conductor is suitable for use at temperatures not to exceed 90°C, dry locations or 75°C wet locations or not to exceed 75°C when exposed to oil or coolant.

Conductor temperatures not to exceed 105°C in dry locations when rated AWM and used as appliance wiring material. Voltage rating for all applications is 600 volts.

STANDARD of 600V 8 AWG THHN/THWN building wire

UL 83 - Thermoplastic-Insulated Wires and Cables

CSA C22.2 No. 75-03

UL 1063 (MTW) - Machine-Tool Wires and Cables (stranded cables only)

UL 758 (AWM)

ICEA S-95-658/NEMA WC 70

CONSTRUCTIONof 600V 8 AWG THHN/THWN building wire

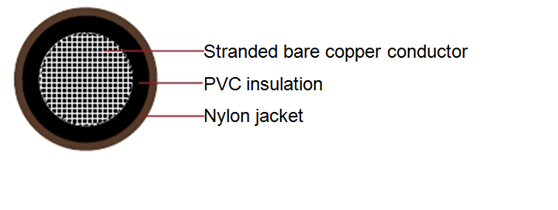

Conductor: Soft annealed bare copper, Class B stranding per ASTM B8

Insulation: Tough, heat and moisture resistant Polyvinyl chloride (PVC) insulation over which a nylon (polyamide) jacket is applied.

Color: upon request, black is preferable

CONSTRUCTION PARAMETERof 600V 8 AWG THHN/THWN building wire

|

AWG |

Strand |

Nominal Insulation Thickness |

Nominal Jacket Thickness |

Nominal Overall Diameter |

Cable weight |

||||

|

or |

|||||||||

|

kcmil |

Inch |

mm |

Inch |

mm |

Inch |

mm |

Lbs/kft |

kg/km |

|

|

14 |

1 |

0.015 |

0.38 |

0.004 |

0.1 |

0.11 |

2.79 |

15 |

22 |

|

12 |

1 |

0.015 |

0.38 |

0.004 |

0.1 |

0.12 |

3.05 |

23 |

34 |

|

10 |

1 |

0.02 |

0.51 |

0.004 |

0.1 |

0.15 |

3.81 |

37 |

54 |

|

14 |

19 |

0.015 |

0.38 |

0.004 |

0.1 |

0.11 |

2.79 |

16 |

24 |

|

12 |

19 |

0.015 |

0.38 |

0.004 |

0.1 |

0.13 |

3.3 |

24 |

36 |

|

10 |

19 |

0.02 |

0.51 |

0.004 |

0.1 |

0.17 |

4.32 |

39 |

58 |

|

8 |

19 |

0.03 |

0.76 |

0.005 |

0.13 |

0.22 |

5.59 |

63 |

94 |

|

6 |

19 |

0.03 |

0.76 |

0.005 |

0.13 |

0.26 |

6.6 |

98 |

145 |

|

4 |

19 |

0.04 |

1.01 |

0.006 |

0.15 |

0.33 |

8.38 |

157 |

234 |

|

3 |

19 |

0.04 |

1.01 |

0.006 |

0.15 |

0.36 |

9.14 |

193 |

287 |

|

2 |

19 |

0.04 |

1.01 |

0.006 |

0.15 |

0.39 |

9.91 |

240 |

357 |

|

1 |

19 |

0.05 |

1.27 |

0.007 |

0.18 |

0.43 |

10.92 |

300 |

446 |

|

1/0 |

19 |

0.05 |

1.27 |

0.007 |

0.18 |

0.47 |

11.94 |

376 |

560 |

|

2/0 |

19 |

0.05 |

1.27 |

0.007 |

0.18 |

0.52 |

13.21 |

467 |

695 |

|

3/0 |

19 |

0.05 |

1.27 |

0.007 |

0.18 |

0.57 |

14.48 |

581 |

864 |

|

4/0 |

19 |

0.05 |

1.27 |

0.007 |

0.18 |

0.64 |

16.26 |

724 |

1077 |

|

250 |

37 |

0.06 |

1.52 |

0.008 |

0.2 |

0.69 |

17.53 |

855 |

1272 |

|

300 |

37 |

0.06 |

1.52 |

0.008 |

0.2 |

0.76 |

19.3 |

1022 |

1521 |

|

350 |

37 |

0.06 |

1.52 |

0.008 |

0.2 |

0.79 |

20.07 |

1191 |

1772 |

|

400 |

37 |

0.06 |

1.52 |

0.008 |

0.2 |

0.85 |

21.59 |

1345 |

2001 |

|

500 |

37 |

0.06 |

1.52 |

0.008 |

0.2 |

0.94 |

23.88 |

1668 |

2482 |

|

600 |

61 |

0.07 |

1.78 |

0.009 |

0.23 |

1.1 |

27.94 |

1994 |

2967 |

|

750 |

61 |

0.07 |

1.78 |

0.009 |

0.23 |

1.16 |

29.46 |

2465 |

3668 |